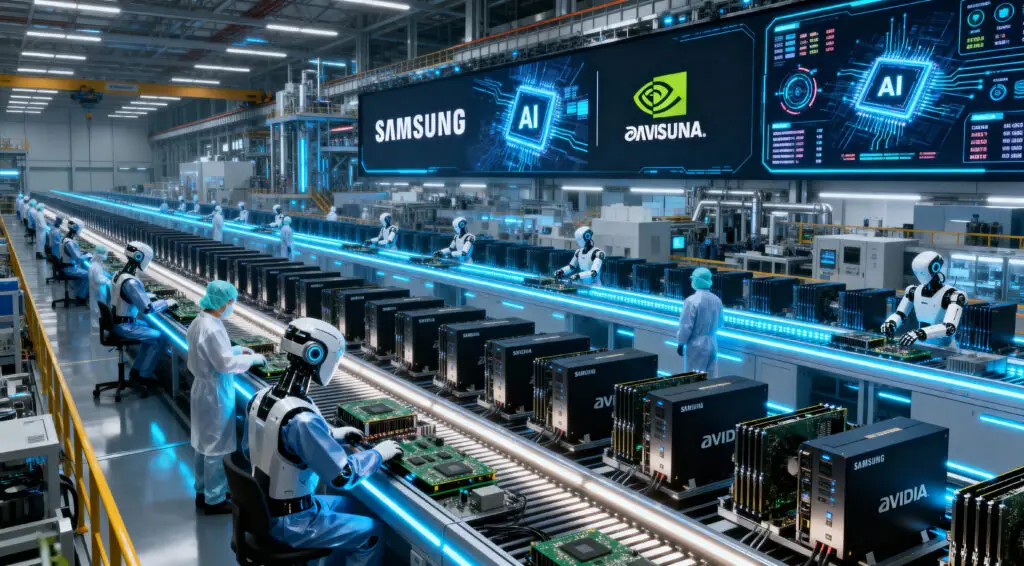

Samsung and NVIDIA Unveil Ambitious AI Megafactory Project

Samsung Electronics and NVIDIA have teamed together to build a new AI megafactory in South Korea a major step toward AI-powered manufacturing. The facility will use more than 50,000 NVIDIA GPUs and cutting-edge Omniverse technologies to bring semiconductor, mobile, and robotics production into the 21st century.

Samsung’s biggest digital transformation project to date integrates artificial intelligence into all parts of manufacturing, from chip design and quality control to predictive maintenance and productivity optimization.

Source: Business Standard

Revolutionizing Manufacturing With AI and Real-Time Data

The goal of the AI Megafactory is to connect all of Samsung’s operations worldwide into one intelligent network. Using NVIDIA’s AI and accelerated computing platforms, the system will constantly analyze and forecast production data, making manufacturing processes faster, smarter, and more efficient.

Samsung’s enhanced data integration will allow its factories to monitor performance in real time, respond instantly to production anomalies, and automate workflows across semiconductor and mobile device lines.

A Partnership Made Stronger by Years of Innovation

Samsung and NVIDIA have been partners for more than 25 years. Their collaboration began when Samsung’s DRAM powered NVIDIA’s first graphics cards and has evolved through decades of technological innovation.

Today, the partnership extends to high-performance computing, with Samsung developing next-generation HBM4 memory built on 10nm-class DRAM and a 4nm logic base device capable of reaching speeds up to 11 Gbps. These advances are expected to power the AI-driven infrastructure of the future.

Recommended Article: Spotify Jam Arrives on Android Auto Bringing Shared Music Control

Scaling Intelligent Manufacturing Through Digital Twins

A key element of Samsung’s AI Factory is the use of digital twins, virtual replicas of entire fabrication facilities built using NVIDIA Omniverse. Engineers can simulate production environments, identify inefficiencies, and optimize operations before implementing changes in the real world.

By combining Omniverse with NVIDIA’s cuLitho and CUDA-X libraries, Samsung has already accelerated computational lithography by 20×. This breakthrough enables faster, more precise semiconductor design and wafer patterning.

Advancing AI Robotics and Autonomous Systems

Beyond chip production, Samsung aims to redefine industrial robotics. The company is integrating real-time AI reasoning into humanoid and factory robots through NVIDIA’s RTX PRO 6000 Blackwell and Jetson Thor platforms.

These systems enable robots to perceive complex environments, make autonomous decisions, and perform precise physical tasks. Incorporating robotics into the AI Megafactory highlights Samsung’s shift toward “practical AI”, where intelligent machines learn, adapt, and safely collaborate with human workers.

Expanding AI Infrastructure to Global Operations

Over the next few years, Samsung plans to extend its AI megafactory model to international hubs, including its advanced semiconductor plant in Taylor, Texas. This expansion will unify AI-driven processes across Samsung’s global supply chain, enhancing both efficiency and resilience.

The company is also working with EDA partners to develop GPU-powered design tools that accelerate electronic design automation. These AI-assisted tools streamline collaboration among engineers and reduce design cycle times.

Making the Future of AI-Powered Connectivity

Samsung and NVIDIA are jointly developing AI-RAN, a next-generation communication system that merges AI computing with mobile networks. AI-RAN will enable connected devices such as drones, robots, and industrial systems to operate in real time by placing intelligence at the network edge.

This AI-enhanced connectivity acts as a “neural network” for physical AI, allowing instant data processing and decision-making. It bridges the gap between cloud-based intelligence and real-world execution shaping the future of connected, intelligent manufacturing.